Operators and Quality Commitment

Sahana is dedicated to delivering excellence from fiber to fashion, ensuring the highest level of customer satisfaction. Our experienced sampling operators and quality team work to create meticulously crafted products with a first-time pass capability.

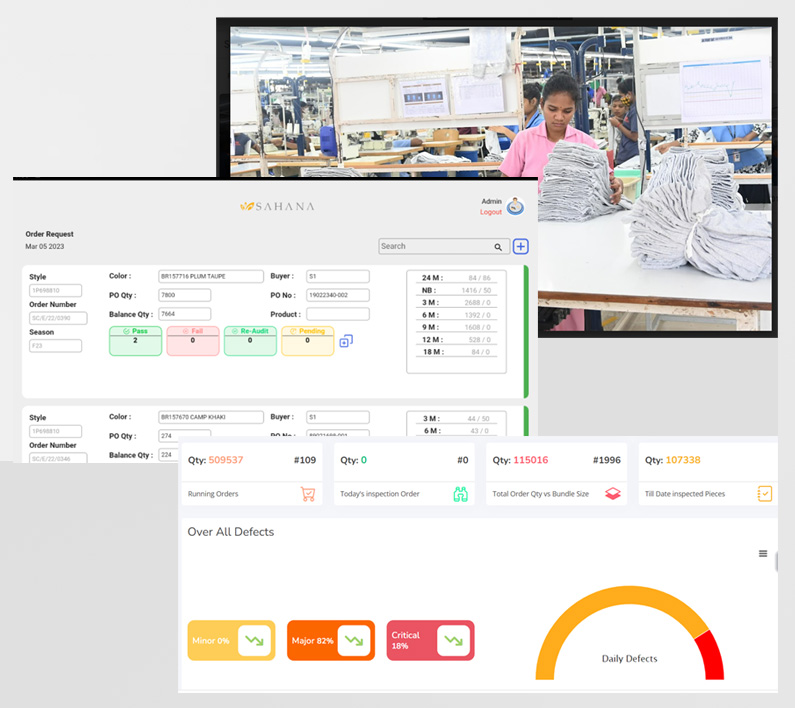

Technology & Digitalization

Industry 4.0 & IoT Integration: Heavy investment in technology to digitalize the factory.

Sewing IoT Implementation: Enhances performance for both workers and machinery.

Real-time Quality Monitoring: AQL inspection process digitized for better decision-making and garment quality improvement.

Fabric & Garment Inspection

Fabric Inspection: 100% of fabric rolls are inspected at both grey and received stages using the four-point fabric inspection method to reduce cut panel rejections.

Garment Quality Control: AQL cross-audit at AQL-1.0 Level II to manage end-line errors and achieve a final 100% accuracy rate.

Safety & Precision Measures

Needle & Sharp Tool Policies: Protects both customers and employees from harm.

Metal Detection: Devices with 1.0 sensitivity level and a 24-point calibration system prevent metal or needle pieces from appearing in final garments.